If you're looking for the correct bucket teeth, your […]

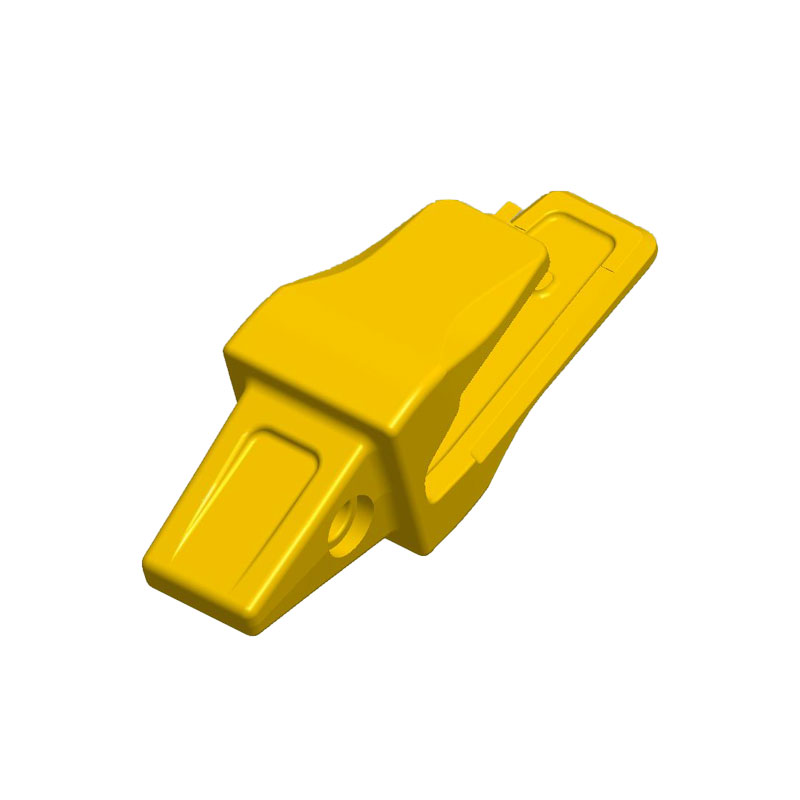

If you're looking for the correct bucket teeth, your machine has a specialized adapter. The hammerless design of the teeth makes it possible to fit the correct adapter onto your bucket. However, OEM parts can be very expensive compared to aftermarket parts. This is because they have a monopoly on adaptor teeth, which locks you into a single supplier. You may need to replace the bucket teeth adaptors to use a widely available model.

If you're looking for bucket teeth, first measure the inside pocket opening of your bucket. Then, compare the size of the pocket opening with the dimensions on the product listing. If the measurements match, you've got the right product. Otherwise, if they don't match, you'll have to hammer the pins. It may take a little practice, but it's a good way to make sure you're getting the right bucket teeth.

Bucket teeth are often forged, and they're often made of an alloy of molybdenum and nickel to resist wear and abrasion. Forged bucket teeth have higher wear resistance and can be more durable than those made of cast steel, but the tooling cost is higher. Compared to cast bucket teeth, forged bucket teeth are more costly and can't be reshaped easily. A better way to make bucket teeth is by using a machine with high breakout force, but don't forget to research how to use them.

Another important factor to consider when buying a bucket tooth is its size. It needs to fit the machine well and the machine itself. Having the correct size is crucial for ensuring proper fit and proper penetration. Choose a size larger than your machine's capacity. Then select the tooth size that will work best with your application. Choose between the two. There are many different tooth types available on the market, and you can select the one that suits your needs best.

A skeleton bucket has gaps between teeth and allows finer materials to fall through them. Because it has gaps between teeth, the larger chunks of material can fall through the gap between them, allowing your job to progress. Those are the two most common types of bucket teeth. It's important to choose the right one for your needs, and to keep the maintenance costs as low as possible. But make sure you have one that's made for the job in hand.