One of the main benefits of stainless steel casting i […]

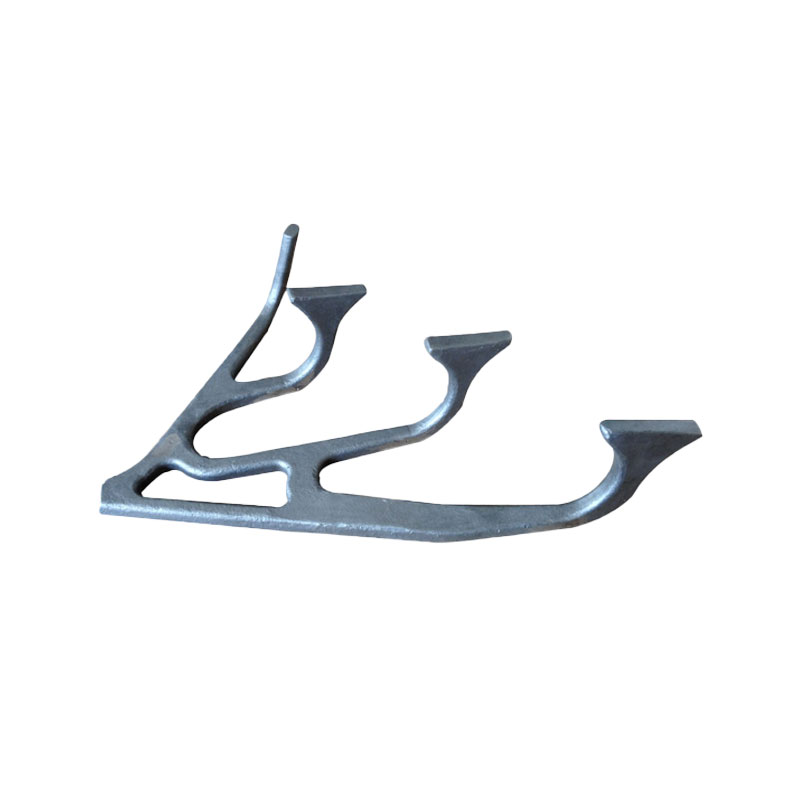

One of the main benefits of stainless steel casting is its ability to produce complex shapes with minimal machining. This metal is also extremely ductile and has no quantity limitations. This process works by melting wax in a mold. The melted wax pattern is then coated with layers of ceramic or stucco material and is then poured with the desired alloy. The process is called lost-wax casting and originated from the concept of melting wax. It is more expensive than other processes, but is an excellent solution for reducing tooling costs.

In the case of stainless steel casting, a variety of different heat treatments are used to enhance its mechanical properties. During the process, the metal is heated to high temperatures and maintained at a constant temperature. The excess phase is then dissolved into a solid solution and the metal is cooled rapidly. This heat treatment is effective at reducing internal stresses and increasing the mechanical properties of cast stainless steel components. This makes them easier to handle and maintain.

If you're in the market for stainless steel casting parts, you have several choices. First, you can choose the material you want to use. Stainless steel is the best choice for parts that are exposed to moisture and water. This metal can be corroded over time, causing problems with precision parts. Then, the process is also more expensive. This means that you'll save money over time by using stainless steel parts.

Another option for stainless steel casting is known as solution treatment. In this process, the material is heated to a high temperature and is held at a constant temperature. The excess phase is dissolved into a solid solution and the metal is cooled quickly. This process will greatly improve the mechanical properties of your cast stainless steel parts. However, it is also more expensive than other methods, as it requires more labor and materials.

Stainless steel casting is highly useful in various industries, including marine and shipbuilding. Other industries that use this metal include bulk materials handling equipment, buildings, roofing, and automobile components. It is also used in pollution control. In addition to being rust-resistant, stainless steel is also resistant to heat, chemicals, and corrosion. This means that stainless steel is often the best choice for manufacturing products in the marine industry. So, if you're in the market for parts, consider using a company that offers high-quality and high-precision stainless steel casting.

The process of making stainless steel parts can vary. There are many types of cast stainless steel parts. Some of these are designed to be thinner, while others have higher tolerance requirements. For example, a small, thin-walled part can be produced in a pre-coated sand casting method. For smaller parts, this type is ideal. It is cheaper than a silica sol investment-casting process and can be used for small and medium-sized items.