Carbon steel is one of the most common and widely used […]

Carbon steel is one of the most common and widely used metal alloys. It is highly versatile, cost-effective, readily available, and possesses great strength, wear resistance, and durability.

Its mechanical properties are dependent on the proportion of carbon in its composition and alloying elements, such as chromium, nickel, and molybdenum. Changing the balance of these elements, and changing casting and heat-treating practices can change a wide range of characteristics for a cast carbon alloy, from ductile to hard and strong.

Increasing the proportion of carbon in a cast alloy makes it more ductile and less brittle. Higher carbon content also lowers the melting point of the alloy, thereby increasing its resistance to welding.

In addition, increasing the proportion of carbon in a steel alloy produces a stronger material. This property can be improved through heat treatment, but the strength may be reduced if the temperature of the heat treatment exceeds the tensile strength of the steel.

Characteristics of cast irons and cast steels:

Typical physical, mechanical, and corrosion properties of cast irons and cast steels are similar to those of wrought irons of the same composition. However, the microstructure of cast steels is different from that of wrought irons. This microstructure affects the chemical, electrical, and thermal conductivity properties of the steel as well as its abrasion and wear resistance.

Characteristics of low-alloy cast steels:

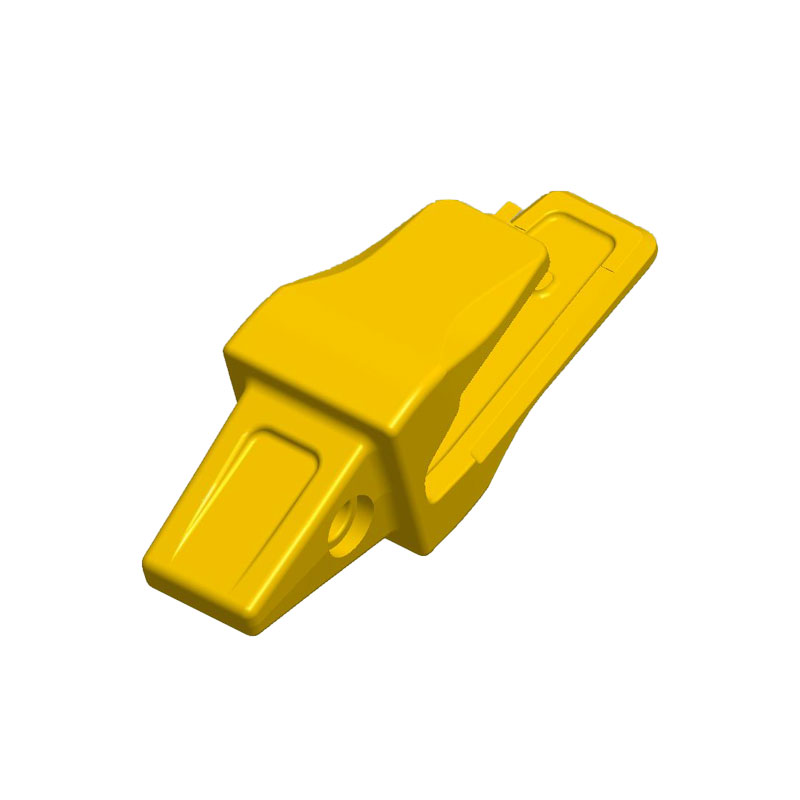

Low-alloy cast steels contain a specified amount of chromium, nickel, or molybdenum added to the carbon to enhance the strength and toughness of the steel. These steels are usually used for components in the oil and gas, pump and valve, and military vehicles industries.

https://www.tosing-casting.com/product/