The process of crafting stainless steel casting parts i […]

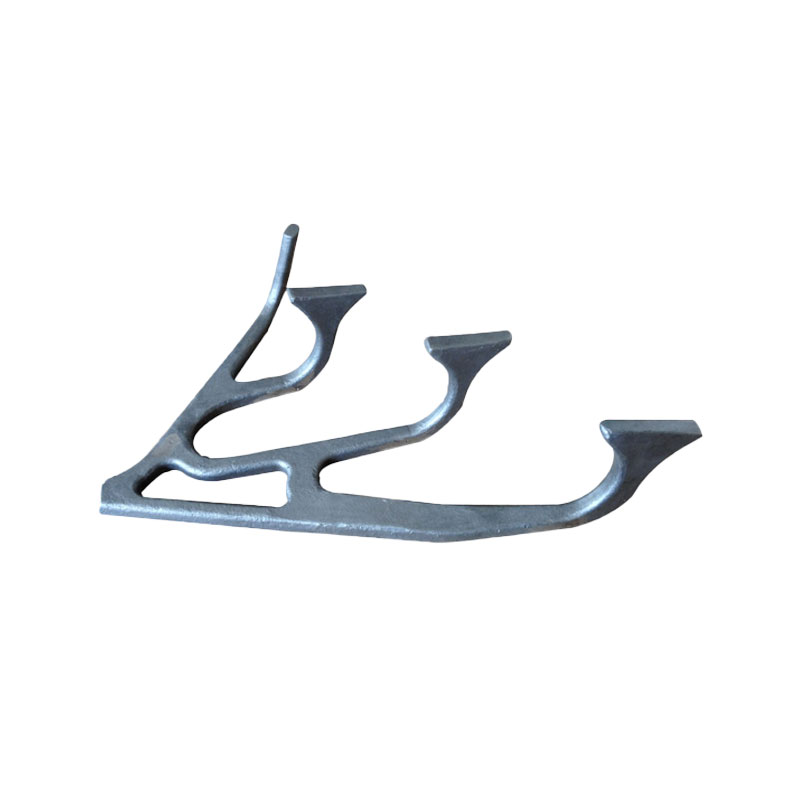

The process of crafting stainless steel casting parts is a fascinating journey. It involves transforming molten metal into intricate and precise forms, resulting in durable and high-quality components that are used in a wide range of industries.

The first step in this artful process is the creation of a wax or plastic pattern. This pattern is an exact replica of the desired stainless steel part. Skilled artisans use various techniques, such as injection molding or 3D printing, to produce these patterns with intricate details and precision.

Once the pattern is created, it is then attached to a wax or plastic runner system. This system allows for the easy flow of molten metal during the casting process. The pattern, along with the runner system, is then dipped in a ceramic slurry, also known as investment material.

The investment material forms a ceramic shell around the pattern, creating a mold. This mold is then heated, causing the wax or plastic pattern to melt and be removed, leaving behind a cavity in the shape of the desired part.

With the mold prepared, it is time to move on to the main event - pouring the molten stainless steel. The molten metal, often heated to extreme temperatures, is carefully poured into the mold. Skilled craftsmen ensure that the pouring process is precise and controlled to avoid any defects or imperfections in the final product.

Once the molten metal has solidified, the shell is broken away, revealing the newly created stainless steel casting part. The part goes through rigorous quality control checks to ensure it meets the required specifications and standards. Machining, grinding, or polishing may also be done to further enhance the part's appearance and accuracy.

The art of stainless steel casting requires a combination of technical expertise, precision, and artistic skill. It is a delicate dance between the science of metallurgy and the craftsmanship of creating highly detailed and accurate patterns.

The advantages of stainless steel casting parts are numerous. Stainless steel offers excellent corrosion resistance, making it ideal for applications in harsh environments. It also possesses high tensile strength, making it suitable for heavy-duty purposes. Additionally, stainless steel has a visually appealing aesthetic and is easy to clean and maintain.

In conclusion, the process of crafting stainless steel casting parts is a true masterpiece. From the initial creation of patterns to the intricate pouring of molten metal, skilled craftsmen bring life to stainless steel. These components play a crucial role in various industries, boasting strength, durability, and corrosion resistance. It is a testament to the artistry and engineering behind the creation of stainless steel casting parts and the transformative power of molten metal.