You can cast a metal part in a variety of ways. The bas […]

You can cast a metal part in a variety of ways. The basic approach to metal casting is to fill a casting with liquid metal. The exception is tin bronze, which can be solidified through a different process. During the casting process, the liquid metal fills the casting gradually, beginning in thin sections and solidifying last in feeder heads.

The master pattern is the blueprint for a metal casting. Without a good pattern, a piece will deform or crack during production. The right pattern ensures a clean and detailed casting. However, not all patterns are created equally. You should consider the type of metal and mold before making a pattern.

The size of the master pattern should be the same as the final casting. Brass casting castings are made with a Sb (Si), while aluminum castings are made with Ca. This is a good rule of thumb to follow. The larger the master pattern, the more accurate the final casting will be.

Creating a master pattern is a very labor-intensive process. For this reason, manufacturers are increasingly turning to 3D printing. It saves both time and money and can be used for creating repeatable moulds for direct casting.

There are many ways to make a core box. A common way is by using a hot-box process. This process involves packing sand with a binder and then heating the box to about 230 deg C (446 F). As the binder touches the hot surface of the core box, it begins to cure within 10 to 30 seconds. Some binder types require further baking to cure. Another way to make a core box is by making a shell-core.

Cores are a vital part of the metal casting process. They help keep the molten metal from filling the entire cavity of the mold. In some cases, multiple cores are required for a more complex casting.

The first step to making metal castings is creating a mold cavity. For this, you must use a pattern. You may use a CAD system to design the mold. After you've designed the pattern, you can pack material around it, forming the mold cavity. Next, you'll add a core, which is a solid material placed inside the mold cavity. This core creates the interior surface of the casting.

This step ensures that the metal pours into the mold cavity at the appropriate rate, so that the process will not result in air or loose sand washing out. A proper pouring rate will create the desired temperature gradient, and a slow pouring rate will help the metal give up some of its heat to lower parts.

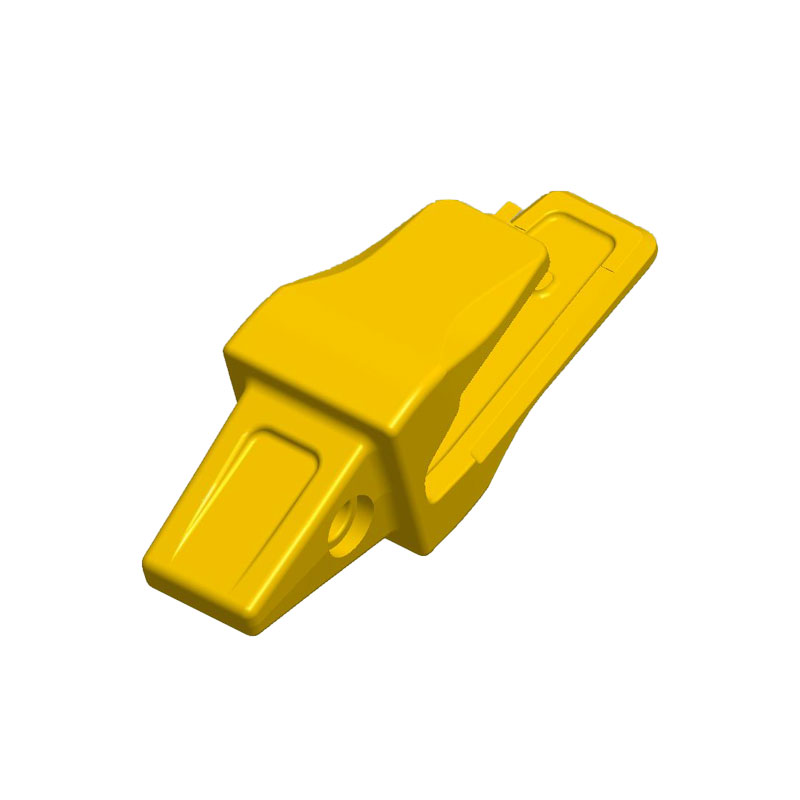

product name: Machining SS Casting Parts accessories

Product description:

Process: Silica sol Process

Material: Stainless Steel

Standard: ISO, DIN, GB, AAR, BS

Max Size: 500mm

Weight: 0.005-30kgs

Tolerance: CT3-7

Year Capacity: 20000 T

Stainless steel parts are one of the most widely used metals in manufacturing. This metal is very suitable for cars, trains and space shuttles, as well as gears, belts, wheels and many other industrial products that need to be strong, durable and light. Stainless steel parts are very durable and can withstand heavy use, so they are suitable for almost any project. If you are interested in purchasing certain stainless steel parts, we can customize products according to your needs.

For more details, please visit it Machining SS Casting Parts accessories

Welcome to mail: penny@tosing-casting.com or call + 86-574-88545657