Ground engaging tools (GETs) are detachable attachments […]

Ground engaging tools (GETs) are detachable attachments for excavators and loaders. They serve two main functions: to reduce the impact of the machine on the ground, and to provide different levels of tip penetration into the soil. These tools can be used on loaders, excavators, scrapers, and other machines. These attachments are useful in construction, mining, forestry, and other industries.

Maintenance of GETs

Regular maintenance is essential to prolong the life of ground engaging tools. Regular inspections will reveal any damage or excessive wear. Identifying the issue early will help you avoid major breakdowns and costly repairs. If you can't perform the inspections yourself, ask a Komatsu specialist for help. This professional can assist you in the inspection process and provide you with tips and recommendations on how to ensure the safety and reliability of your ground engaging tools.

GETs, or ground engaging tools, are important components of construction equipment. They require durable materials that can withstand heavy use. They can be attached to excavators, loaders, scrapers, and other heavy equipment. They are available with a wide range of attachments that provide different levels of tip penetration. They are used for a variety of tasks, including mining, forestry, and construction.

Ground engaging tools must be maintained properly to prevent them from compromising the productivity of the operation. Getting them to their recommended maintenance interval can extend their life and reduce maintenance costs.

Getting the most out of your GETs

Getting the most out of your Ground Engaged Tools (GETs) is essential for any business, as it helps increase productivity and pleases clients. With the help of GETs, workers can get more work done in less time. These machines are extremely efficient, and they offer a range of benefits.

The main advantage of using GETs is that they can help reduce impact and wear. They also absorb shock, thereby extending the life of the equipment. They also help prevent damage to the internal components of a machine. These benefits can help you save time, money, and resources.

Preventing premature breakdowns

When it comes to heavy equipment, preventing premature breakdowns is an important part of equipment maintenance. By following some simple steps, you can prevent unplanned machine downtime and stoppages, which can be costly. Read on for some helpful tips. The first step is to regularly inspect your ground engaging tools. Regular inspections will help identify excessive wear and damage. If necessary, arrange bucket inspections by a Komatsu specialist.

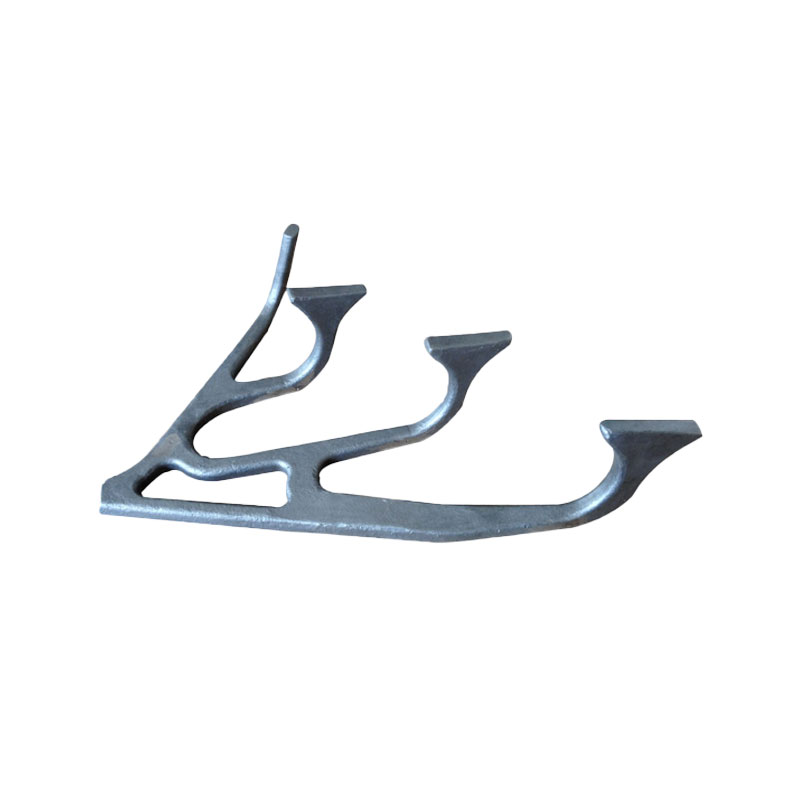

product name: Excavator Parts Twin Tiger Tip Bucket Teeth

Product description:

Part Name:Teeth

Process: Water glass

Material: Carbon Steel, Alloy Steel

Standard: ISO, DIN, GB, AAR, BS

Max Size: 1000mm

Weight: 0.2-90 kgs

Tolerance: CT8-9

Year Capacity:20000 T

For more details, please visit it Excavator Parts Twin Tiger Tip Bucket Teeth

Welcome to mail:[email protected] or call 0086-574-88545657