The Investment Casting Process Advantage The investment […]

The investment casting process involves pouring metal into a mold and then forming the part with a wax pattern. The first coat of this process is crucial to the superior surface finish of the final product. Then, a series of slurries are applied to the assembly to make it more solid. The moulds are left to dry for eight to 24 hours. Then, they are coated with increasingly coarse fused-silica sands.

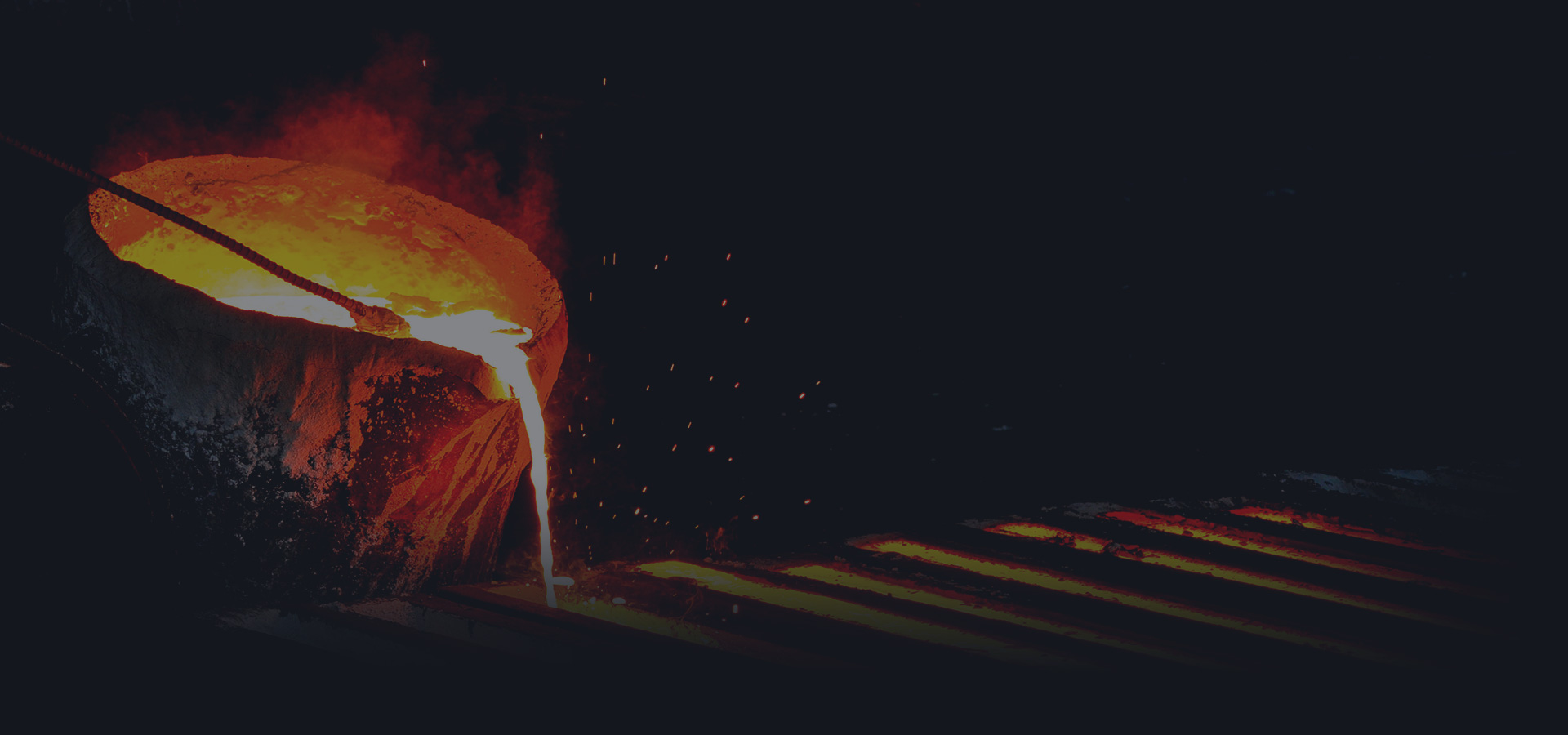

After the molten metal is injected into the die, it solidifies. The molten metal then exits the mold. The casting is then finished. The dimensional accuracy is important, but it is not as accurate as the machining process. If you require large parts with very low tolerances, die casting is the better option. In most cases, the tolerances of investment casting are so tight that machining is not necessary.

The investment casting process starts with a wax pattern. The pattern is attached to a hardened ceramic mold and then heated to around 200F (90C-175C). The wax is then melted inside the mold, resulting in a finished object. It is important to note that this process takes at least six weeks to complete. However, if the project is small, this can be completed in less than three weeks. If you don't have the time to make the wax pattern yourself, you can use a 3D printer to create one.

An investment casting pattern can be made from a wax model. The master die is machined. Before the part is cast, a wax investment casting pattern is created, which must be precisely calculated. This mold will then be used for the casting process. Although the pattern is destroyed during the investment casting process, it can be reused. The wax mold can be machined if you don't mind the costs. The molds can be reused after the casting process is finished.

The next step of the investment casting process is the coating. During this stage, the ceramic mould is coated with a liquid refractory material. After the pattern is poured into the mold, the molds are hardened. During this process, the ceramic mould is covered with the liquid material, and the process is called stuccoing. It is the first step of the process. After the staining is complete, the clay is cured.

A close design review is the most important aspect of the investment casting process. The closer the design is to the finished part, the less machining is needed to produce the desired product. Often, the design phase will include many details and components that may not otherwise be possible to achieve with die casting. These details will be visible to the customer, and this can make the entire process more efficient for the company. The final piece is more reliable than any other part made using the investment casting process.

The shrinkage rate of an investment casting depends on the material used. The type of metal used will determine the amount of shrinkage. In addition to stainless steel, aluminum, magnesium, bronze, and copper alloys are some of the most common. This process is best suited for high-quality precision parts, such as those that require complex geometry. It also requires a pre-heated ceramic mold, which prevents uneven cooling of the molten metal.

An investment casting is useful for a number of reasons. It is a cost-effective manufacturing process, but it is not an economical choice for every application. The high initial costs make it an attractive option for smaller projects, but investment casting is also a valuable resource for designers. It is also an effective method for thin-walled applications. The process is highly accurate and focuses on consistency, which is essential in a high-precision part.

The investment casting process produces high-precision parts with complex geometry and high-temperature requirements. The investment casting process can be used for automotive and military parts, and it has advantages over sand casting. Furthermore, the process can be highly expensive. Nevertheless, the upfront costs are worth it for large-scale businesses that require small-scale production. Most manufacturers of small-sized parts should choose investment casting if they want to save on cost.

The advantages of investment casting are manifold. Unlike traditional manufacturing methods, this process requires minimal finishing after production. It eliminates the need for secondary machining and other processing steps. Moreover, the parts produced by investment casting are perfect and flawless, eliminating the need for secondary machining or other processes. Those who prefer this method of manufacturing should take a look at the following reasons. Next, we will discuss these benefits of investment casting.

It is possible to produce complex shapes and sizes, allowing for low-weight and thin walls. Additionally, a correct investment casting material can reduce the need for secondary machining processes. The properties of final parts are directly proportional to the material's properties, making this type of manufacturing a highly efficient method of production. The advantages of investment casting cannot be overstated, however. The process is highly customizable, allowing you to create an infinite variety of products.

This process is ideal for producing complex shapes and is an economical choice for many manufacturers. Aside from being affordable, it also has an excellent record of producing intricate details. To get started with an investment casting job, all you need is a wax pattern and a mold. Both materials are easily available in most localized retail stores. Once the mold is made, the molten metal is poured into it, which creates a perfect replica of the wax pattern.

During the investment casting process, your components are cast in a mixture of resins and metals. During this process, you'll need to apply a wax pattern or a wax model. In some cases, 3D printing technology can help you make a wax pattern. Once the wax pattern is completed, it is attached to a wax tree and used for the molding process. The final result is a high-quality part.

Another important factor for determining the quality of investment cast parts is their size. With this process, you can produce one-piece investment cast parts in a single process. Besides, these parts require relatively little maintenance. You can also use an investment casting mold if you want to produce small-scale items. The manufacturing cost of this process is usually very affordable, especially when compared to other types of metalworking. For the average person, a single casting mold costs less than $50.

Another benefit of this process is that it can be customized easily. By using the same wax pattern as the original one, you can easily add logos and even product IDs to investment casting parts. This process also has the added advantage of having a very smooth surface, which is an essential characteristic for investment castings. Moreover, it is much cheaper than most other types of casting, and you'll be able to use the wax pattern from casting to casting for your other products.

Regardless of how many parts you need, investment casting is an excellent choice for manufacturers. The accuracy and precision of the parts can be very important for certain industries. If you need to produce a large volume of parts, investment casting is an excellent option. It is also affordable and versatile, so you should consider this technique for your manufacturing process. If you are interested in investing in this process, you can choose from different types of moulds. If you're looking for dimensional accuracy, you may want to consider using a mould made of ceramic material.

In contrast to traditional manufacturing processes, investment casting is an excellent choice for parts that require complex details. The method is advantageous for producing precise, as-cast parts. It is also useful for making small and complex products. The process also produces excellent as-cast surface finishes. Whether it is a large or small part, it can be cast in a variety of shapes. In addition, it is a great choice for those who need a unique part.

Regardless of the end-use for your component, investment casting is the best way to produce finished products in large volumes. The process involves forming wax patterns and assembling them on a metal die to produce a finished product. It is also a great option for high-volume production. The cost of investment casting depends on the volume, but you can save a lot of money by avoiding expensive manufacturing costs. Once you have your final product, you can be confident it will work for years.