Casting carbon steel electric power parts is a complex […]

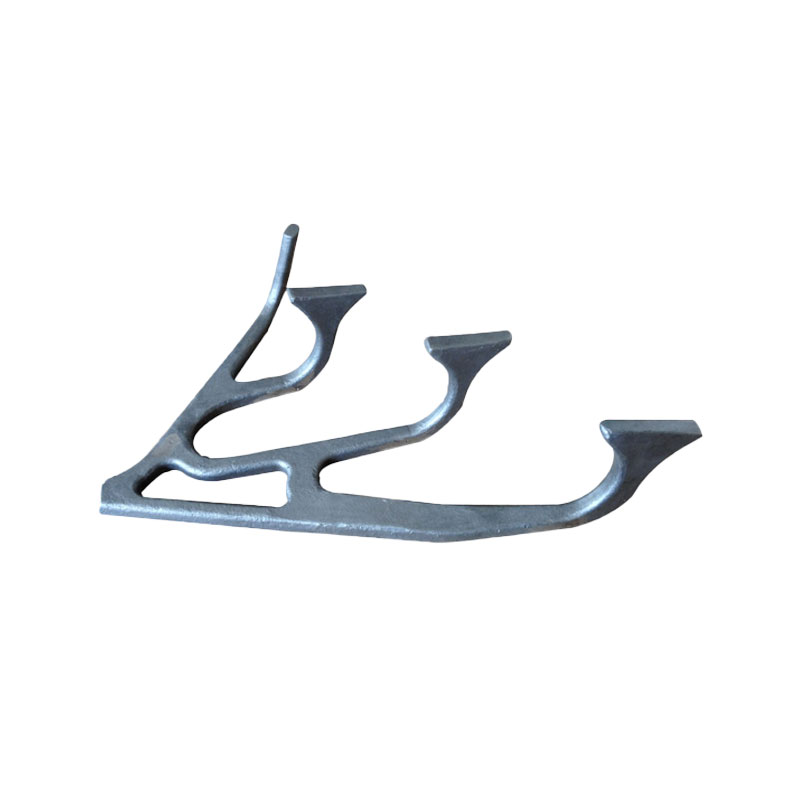

Casting carbon steel electric power parts is a complex and intricate process that requires precision, expertise, and experience. The process involves melting steel, pouring it into a mold, and then allowing it to cool and solidify into the desired shape. Carbon steel is a popular choice for electric power parts due to its durability, strength, and resistance to corrosion.

The first step in the casting process is to melt the steel. This is typically done in an electric arc furnace that heats the steel to a temperature of around 2,800°F. The temperature must be carefully monitored to ensure that the steel is heated evenly and that any impurities are removed. The melted steel is then poured into a ladle and transferred to the molding area.

The molding process is perhaps the most critical step in the casting of carbon steel electric power parts. A mold is created from a pattern that has been designed to the exact specifications of the finished product. The mold is typically made from a refractory material, such as sand, that is able to withstand the high temperatures of the molten steel. The melted steel is poured into the mold and allowed to cool and solidify.

Once the steel has been poured into the mold, it begins to solidify. This process can take anywhere from several minutes to several hours, depending on the size and complexity of the part being cast. As the steel solidifies, it contracts and pulls away from the sides of the mold, creating a cavity in the center of the part. This cavity is called the "riser," and it helps to ensure that the part is fully filled with steel during the casting process.

Once the steel has fully solidified, the mold is broken open and the cast part is removed. The part is then cleaned and any rough edges or surface imperfections are removed. The part may then be heat-treated to improve its strength and durability. This may involve heating the part to a high temperature and then rapidly cooling it, a process known as quenching.

Casting carbon steel electric power parts is a complex and challenging process that requires precision, expertise, and experience. The process involves melting steel, pouring it into a mold, and then allowing it to cool and solidify into the desired shape. The finished product is a high-quality, durable, and corrosion-resistant part that is ideal for use in electric power applications. Whether you are a manufacturer, engineer, or consumer, understanding the art of casting carbon steel electric power parts is essential for ensuring the success and longevity of your products.