Creating a metal casting steel involves a series of ste […]

Creating a metal casting steel involves a series of steps that are designed to ensure the best results. The process starts with selecting the proper alloy, forming the molten metal and then cooling the liquid to a point where it can solidify. After the metal has solidified, a series of processes is carried out to produce a finished product.

Several processes are used for steel casting, and the properties of the finished product depend on the type of alloy and heat treatment. These include alloying metals to improve toughness, or performing specialized heat treatments to strengthen the steel.

Foundries have specialized testing methods to determine the mechanical properties of their products. Usually, a representative cast sample is subjected to controlled tensile loading until failure occurs. These can be used to identify defects or problems, and also to check for surface finish.

In addition to the standard tensile test, castings are also subjected to impact properties, which measure the energy required to break a standard notched sample. These tests are important because they allow for quick adjustments before casting. The result is a more accurate and consistent representation of the entire heat of the metal.

Properties

Several studies have been carried out to study the properties of casting steel. Among them are: determining the effect of microstructure on mechanical properties, and the effectiveness of various techniques to eliminate defects. Some of these studies have been published in a number of journals. Metallurgical Transactions A, Materials Science and Engineering, and Ferrous Metallurgy. These studies demonstrate the importance of the process of refining the material to increase its performance.

Other studies have focused on ultra-high strength steel and cold resistance of new castings. The most important technology of producing casting steel products is the process of casting.

The first casting process was evaluated. Surface defects on both sides were measured and their effects on the product's performance were examined. This was done using non-destructive methods such as radiography and liquid penetrant. A tensile test was performed using an all-purpose tensile testing device. After the tensile strength was measured, elongation was measured to calculate the yield strength.

During the solidification process, crystalline structures form in steel. These structures differ depending on the type of steel. In addition, the atoms that compose the crystalline structure vary. Some alloys have a lower carbon content than the parent metal, whereas others contain more. The crystalline structure can be seen under a microscope.

The crystalline structure of a steel can be classified into three types. These are: hexagonal close packed (HCP), face centered cubic (FCC), and body centered cubic (BCC). Each of these structures has its own atomic arrangement.

The best known of these structures is the HCP, which has an atomic structure whose quaternary axes represent the cube. However, there are a number of other crystallographic structures in a steel. For example, martensite is an iron-carbon alloy that contains relatively high levels of carbon. Despite this, it is a strong and durable material.

Limits for silicon and manganese

Increasing the silicon and manganese content in casting steel can increase strength and hardness. However, it can also result in undesirable changes in the surface properties. These changes include an increase in wear and abrasive damage.

In addition, the addition of chromium increases the hardness and tensile strength of the materials. These elements can be combined with suitable heat-treatments to improve the desirable properties. In the present study, the effects of alloying elements on the mechanical and microstructure properties of cast iron were studied. Fig. 9 illustrates the varying levels of hardness and tensile strength of a modified cast iron material containing 2.91% Mn and 3.00% Si.

The results of this study confirm the beneficial effects of adding Cr to grey cast iron. It was shown that the hardness of the material increased by up to nine times, and the tensile strength by up to eight times.

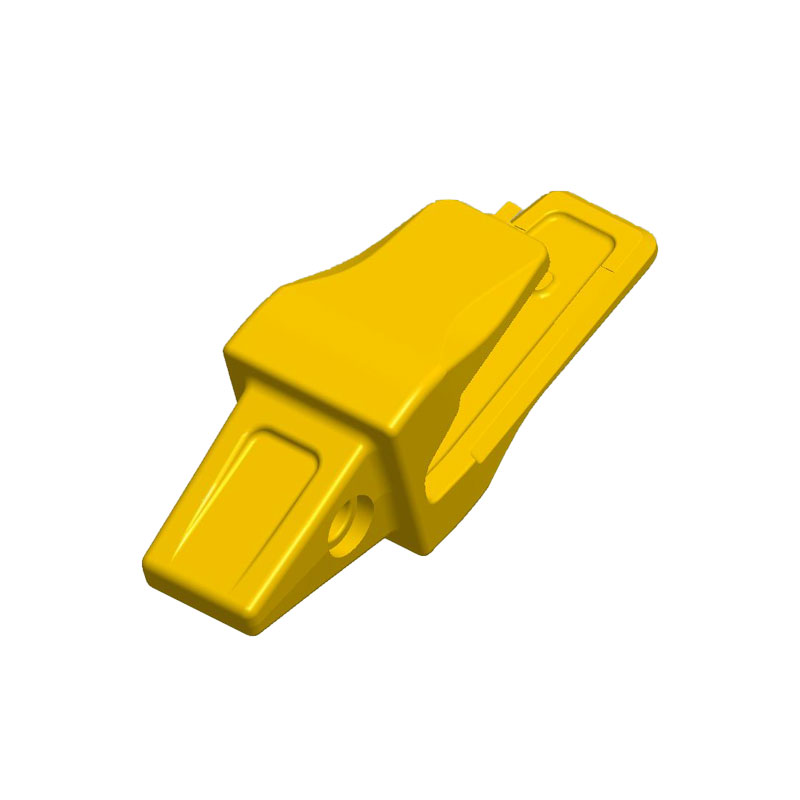

Whether you are in the construction industry or the mining industry, you will surely need tools that are durable and can withstand high stress. Steel and cast iron are the two popular metals used in the industry. They are strong, durable, and corrosion-resistant. They also allow you to create complex shapes and geometries.

Both steel and cast iron have their own advantages and disadvantages. Understanding their characteristics can help you choose the right material for your needs.

Steel is stronger and harder than iron. It is a better choice for certain applications, especially when it comes to tensile strength. However, it wears out faster. Moreover, it is not as ductile as iron.