For a company or business to reap the benefits of OEM […]

For a company or business to reap the benefits of OEM equipment and perform its duties, it needs to have access to the right tools. There are different manufacturers, and each has its own set of credentials and advantages over others. The difference between one OEM tool supplier and another could be in the design and technology they use to provide their customers with top quality tools. When shopping around, it is important that you take your time in researching and checking out the different manufacturers so you can find one that best meets your needs.

Most steel suppliers offer a large variety of professional tools designed for cutting in various environments. Whether you're cutting indoors or outdoors, or you're dealing with steel for another industry like petroleum or coal, there will always be the right tool for the job. In the past, oil refineries needed special tools for efficiently and effectively removing and capturing crude oil from the ground. Now, there are specialized machines used for oil drilling and pumping that have wheels on the bottom to facilitate the movement of the drilling equipment as well as to keep it safe from debris that may otherwise prove harmful to the operator.

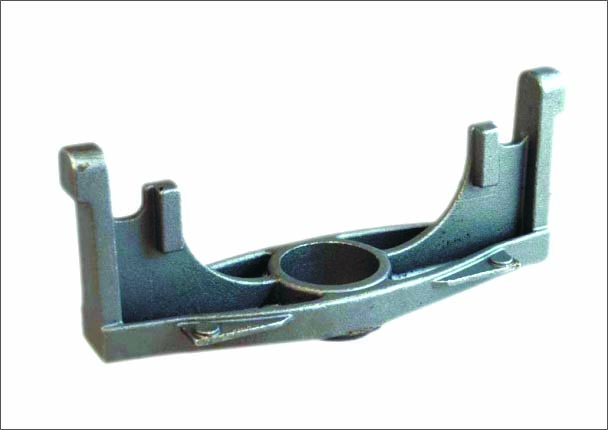

In the process of manufacturing tools, different alloy steels are hardened and tempered to create unique tooling designs. These tooling designs are often used in construction projects. By using the right tools, the amount of force that can be directed into a piece of steel is greatly reduced. As a result, the products you produce from these types of machines are more durable and strong, which means that your equipment will last for a much longer period of time. In addition to steel cutting tools, other specialized machinery are also used to fabricate other tools such as drilling bits, hydraulic presses, and lathes.

OEM equipment and supplies are manufactured to ensure that the tools you buy are of the highest possible quality and will stand up to the toughest work environment. These tools are also designed for heavy duty use so they are not too heavy or too light, so they can be used with a variety of machinery. Because of their durability and reliability, they are generally chosen over other types of cutting tools because they can provide professional results without breaking down.

When purchasing steel cutting equipment, you should ensure that you buy OEM parts from trusted manufacturers. By buying OEM parts, you know that you are getting high quality, durable machinery that is manufactured to specific industry standards. This means that if you use this equipment in your construction projects, it will last you many years and provide you with professional results. Since the steel used to make the equipment is also heat treated, the edges and corners will be smoother and the surface will be stronger.

There are several different brands of steel cutting equipment available in the market today. It is important that you choose a reputable brand so that you are ensured that the tool you purchase is ideal for your needs. In addition, you will be able to find a wide range of tools that have different sizes and power levels, so you can choose one that is suitable for your level of experience. Whether you need a hand-held tool or a table-top model, there will be an OEM product that will suit your needs.