Trains are made up of many different parts that make th […]

Trains are made up of many different parts that make the train run. These parts can vary in size and design to resemble the real thing. They can include trucks and train cars, powered chassis kits, and even air conditioners. Many train parts are also available in HO scale for model railroaders to use. To learn more about the parts of a train, see our articles on Electrical systems, Lighting, and Heating.

Compressed air is used for braking system

The brake system in a train uses compressed air to stop a moving train. The air pressure in the brakeline is constantly balanced with the air pressure in the locomotive. Compressed air is supplied to the brake pipe through a resevoir located under the vehicle. This air pressure is applied to the brake pistons.

Compressed air is also used to power other systems on trains. The braking system, doors, whistles and horns all rely on air. Compressed air is also used to power automatic machinery on ships and subways. It is also used to power a locomotive's suspension system, which helps the rolling stock run smoothly. If an air compressor fails, the suspension system will not function properly. This could cause a turbulent ride for passengers.

Electrical systems

Electrical railway transportation systems are an increasingly popular way to provide transportation for passengers, goods, and services. These systems help reduce the pollution and congestion associated with road traffic, while providing reliable power to locomotives. These electrical systems can use AC or DC current, and can be divided into two categories: fixed power supply systems and railway rolling stock systems. Both types offer advantages and disadvantages. For example, AC provides more stable power over long distances while DC is more cost-effective and easier to use on board the train.

The AC system uses overhead wires. DC systems use the third rail. In both cases, a collector is attached to the train. Until about 30 years ago, the shape of most collectors was a pantograph. In the case of a DC system, the return circuit uses running rails at earth potential.

Lighting

Train layouts often need adequate lighting to provide proper visibility to the passengers and crew. Traditionally, fluorescent tubes were used to light large layouts. These tubes were mounted in a "valence" above the layout. Other lighting systems were then used to illuminate the rest of the room. While fluorescent tubes are still an excellent choice for lighting a train layout, LED lights have the potential to offer better light quality and greater environmental benefits. This innovation could have a major impact on the model railroading industry.

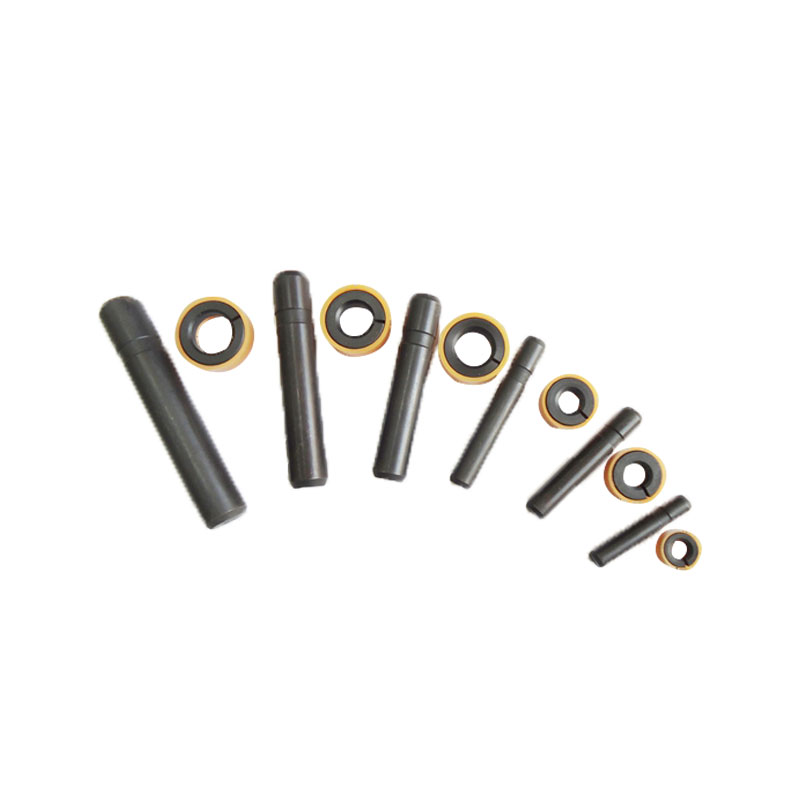

Product name: Carbon Steel Alloy Steel Train Parts

product description:

Process: Water Glass/Silica sol/Pre-coated Sand

Material: Carbon Steel, Alloy Steel

Standard: ISO, DIN, GB, AAR, BS

Max Size: 1000mm

Weight: 0.005-90kgs

Tolerance: CT3-9

Year Capacity:20000 T

For more details, please visit it Carbon Steel Alloy Steel Train Parts

Welcome to mail:[email protected] or call 0086-574-88545657