Welding methods have evolved and now offer many optio […]

Welding methods have evolved and now offer many options for the joining of materials together. Cat weld-on method is one of the most common and widely used methods in the industry. The basic idea behind this technique is to fuse the metal parts in a way that both add strength and form a perfect joint. A strong bond is created because of the added strength from the welded joint and that makes this the most recommended welding method. Since it is very robust and durable, the joints that come out are virtually scratch resistant.

There are several types of the cat and each has its own advantages and disadvantages. Single shot process is the most popular one as it is the quickest process but that leaves minimum scope of customization if desired. This process also produces high quality joints as it eliminates the need of secondary operations like cold work and grinding. In case of multiple shots, the time taken to produce a perfect joint is also less as each individual joint can be tweaked if required during the fitting process.

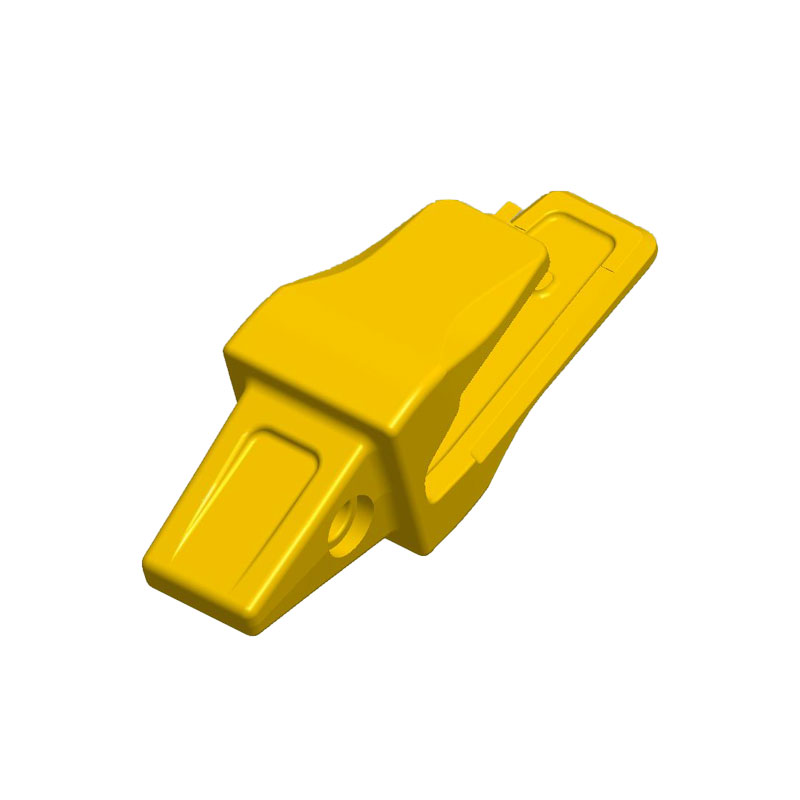

Two types of the weld-on tooth adapters are available based on the process. These include the split process and the traditional process. In the split process, the metal parts are welded together from the outside in a similar way as how the seams in shirts and jeans are joined. The traditional process uses pressurized gases and is very time consuming. It is mostly preferred for low-maintained surfaces because it consumes little time and can be handled by a skilled welder in a short time.

The weld-on tooth Adapters are generally fabricated using TIG (Tungsten Inert Gas) wire which is shielded by heat resistant brazing wire. TIG enables fast heating times and also ensures that the joint is strong enough to withstand stress. The process also involves compressing the gases to prevent sparks during the welding process. Welders can work on any surface with the use of a catheter or without a catheter depending on the type of joints being performed. A variety of grinding, tapping or threading operations can also be done without using a catheter.

The advantages of the cat weld-on tooth adapter over other methods include fast production and flexibility. Since the process does not call for any extra equipment apart from the weld-on filler rod, the entire operation can be carried out at the place of operation with minimal staff and overhead costs. Cat welders can carry out the process in a matter of seconds. The process also allows the user to control the temperature and forces involved to get the joint right. For joints that require more force, higher temperatures are used while for lower forces, lower temperatures are preferred.

An important advantage of using the weld-on tooth adapter is that the users can choose different profiles according to their requirements. If the joint requires a more directed bond, a flat top profile is normally required. For a smoother, more rounded finish, a profile known as a domed profile is normally used. With the use of the cat weld-on tooth, these profiles can be customized to a large extent to provide the best possible results. Welders also have the option of changing the color of the welded areas on the body by coloring the joint after it is completed to match the color of the externally visible portions of the body or suit. This method offers the user great flexibility and ability to customize the final appearance of the body part.