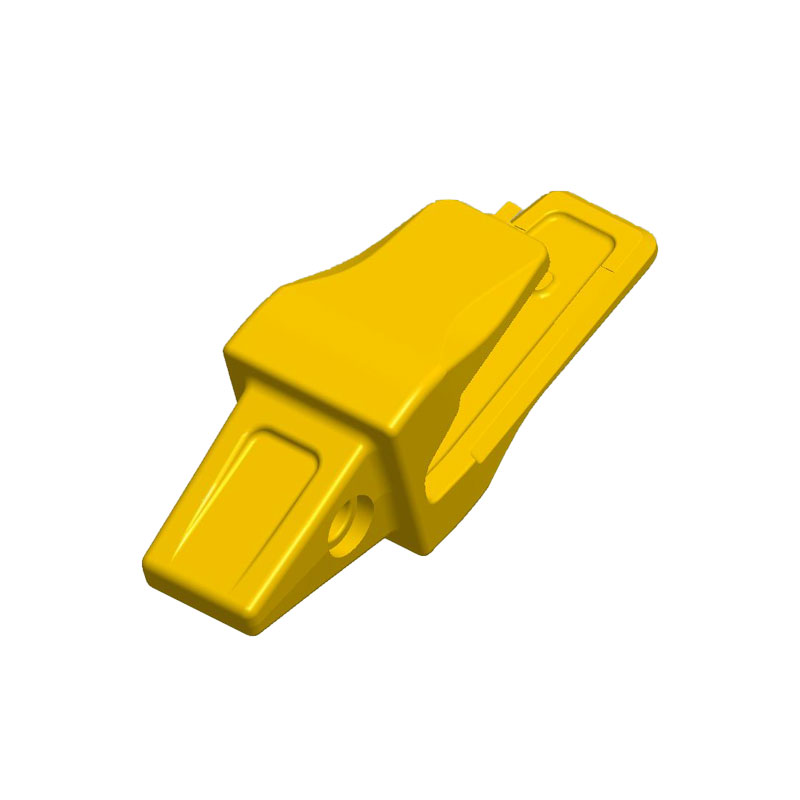

Construction machinery casting parts offer a cost-effec […]

Construction machinery casting parts offer a cost-effective alternative to machining and welding heavy equipment components, which reduces waste in the long run. In addition, they can be made from various metals that are more difficult to machine, such as aluminum, brass, bronze and copper.

Custom manufacturer of die, investment, lost foam, lost wax, sand and spin castings from steel, stainless steel, bronze, copper, aluminum, Inconel(r), gold, silver, nickel, titanium, phosphor bronze, Stellite(r) and tin. Casting processes include air set, continuous, no bake, sand, lost patter, tilt poured and vacuum. Additional services provided are E-coating, heat treating, pattern repair, inspection and assembly.

Agricultural and construction machinery, power transfer, paper, petrochemical, defense, industrial, metalworking and nuclear industries serve as markets. ISO 9001:2008 and Nadcap certified.

Green sand castings from austenitic ductile iron, gray iron, ductile iron and high silicon high molybdenum ductile iron offered. Capable of casting parts up to 28 in. L x 28 in. W x 14 in. H dimensions and tensile strength of 20,000 to 100,000 psi. They are annealed, tempered and enameled, as well as abrasion, acid, heat and corrosion resistant.

CNC machining, vertical CNC machining, robotic polishing and vibratory finishing, heat treating and electric melting services offered. Project management, engineering and design engineering services are also available.