Carbon steel is one of the most widely used materials f […]

Carbon steel is one of the most widely used materials for investment casting. It offers a high level of strength, ductility, and ferromagnetic properties, while also being resistant to corrosion.

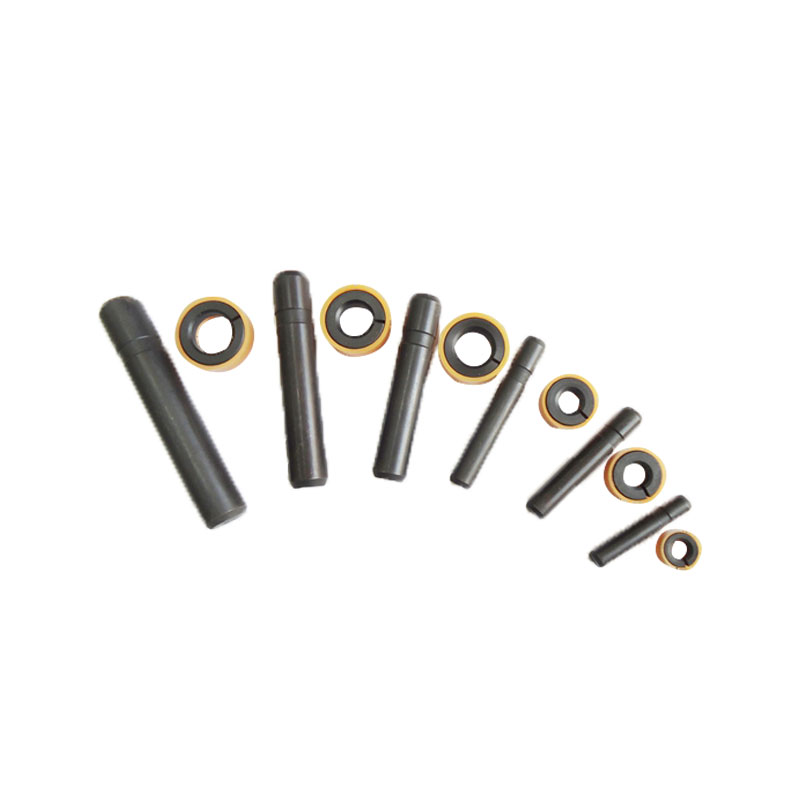

Common applications for cast carbon steel include agricultural equipment, defense and performance-critical machinery in the oil and gas industry. These types of parts typically require precise tolerances and strong structural integrity.

Typical casting processes involve pouring molten iron into a mold. However, steel castings are a more difficult process because they tend to cool and shrink in different ways throughout their internal structures. This can result in large internal voids, or areas of low density.

To minimize these problems, casting foundries perform a variety of inspections to verify specific physical properties of the product. They may use a combination of dimensional inspection, physical testing, and chemical analysis to ensure that the castings meet the requirements of the customer and conform to industry specifications.

Bend property tests are performed to identify a casting’s ductility, as determined by the ability of a rectangular representative sample to be bent around a pin to a particular angle. Impact property tests measure a casting’s toughness by using standard notched samples to test the amount of energy required to break.

The exact content of minor alloying elements in a casting alloy can dramatically affect the material’s chemical composition. This is why chemical analyses are often conducted to verify the accuracy of the alloy’s composition prior to pouring.

https://www.tosing-casting.com/