Carbon steel casting parts are widely known for their e […]

Carbon steel casting parts are widely known for their exceptional mechanical properties, including high tensile strength and hardness. These properties make carbon steel castings ideal for a wide range of applications, from industrial machinery to automotive components.

Carbon steel is a type of steel that contains carbon as the primary alloying element. The carbon content in steel can range from 0.03% to 2.1%, giving it the ability to be hardened and strengthened through heat treatment. The presence of carbon not only increases the strength of the steel but also improves its hardness.

One of the primary factors contributing to the high tensile strength of carbon steel casting parts is the intermolecular forces within the material. These forces, known as metallic bonding, occur between atoms within the crystal lattice structure of the steel. Carbon steel has a crystalline structure in which the carbon atoms are embedded in an iron matrix. The strength of the metallic bonds between the iron and carbon atoms gives carbon steel its remarkable tensile strength.

Another factor is the presence of other alloying elements in carbon steel. Manganese, for example, is commonly added to improve the hardenability and tensile strength of carbon steel. Manganese forms solid solutions with iron, enhancing the strength of the steel without compromising its ductility. Other alloying elements such as chromium, molybdenum, and nickel can be added in varying amounts to further enhance the mechanical properties of carbon steel casting parts.

Heat treatment plays a crucial role in enhancing the tensile strength and hardness of carbon steel casting parts. The heat treatment process involves heating the steel to a specific temperature and then rapidly cooling it to set the desired microstructure. Two commonly used heat treatment methods for carbon steel are annealing and quenching and tempering.

Annealing involves heating the steel to a specific temperature to relieve internal stress and improve its machinability. This process also promotes the formation of a finer and more uniform grain structure, resulting in increased tensile strength and hardness.

Quenching and tempering, on the other hand, involves heating the steel to a high temperature and then rapidly quenching it in a liquid such as oil or water. This produces a hard and brittle structure known as martensite. To improve its toughness and reduce brittleness, the steel is then tempered at a lower temperature. This process results in a microstructure composed of tempered martensite, which exhibits high tensile strength and hardness.

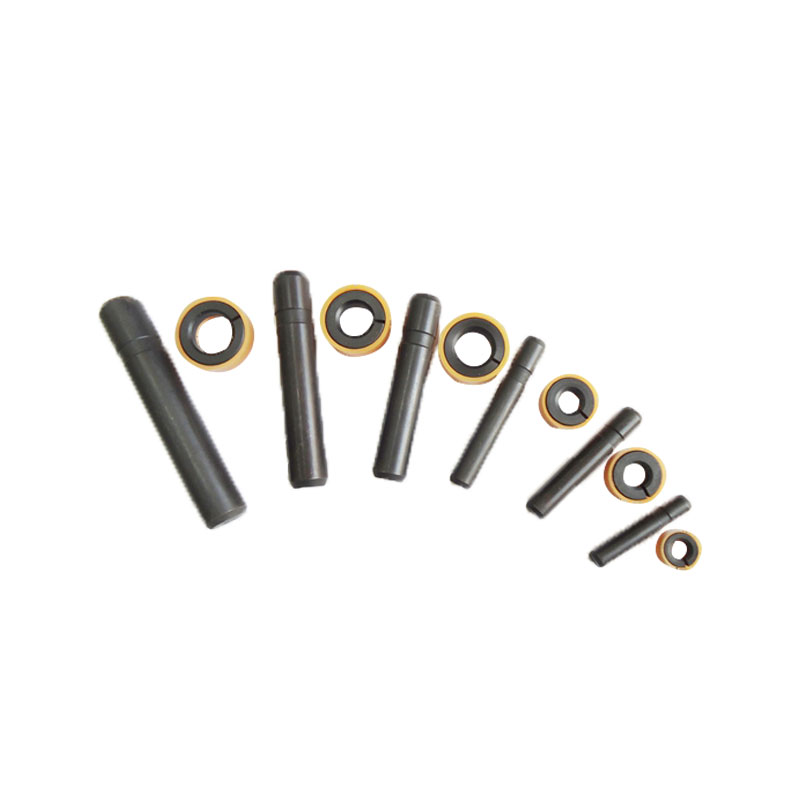

The composition and microstructure of carbon steel casting parts can be further optimized by using advanced casting techniques. Investment casting, also known as lost-wax casting, is a commonly used method for producing high-quality carbon steel castings. This process allows for precise control over the composition and solidification of the steel, resulting in improved mechanical properties.

In conclusion, carbon steel casting parts possess high tensile strength and hardness due to a combination of factors, including metallic bonding, alloying elements, and heat treatment. The presence of carbon and other alloying elements enhances the strength and hardness of the steel, while heat treatment processes such as annealing and quenching and tempering optimize its microstructure. By understanding the factors behind the exceptional mechanical properties of carbon steel casting parts, manufacturers can produce components that meet the rigorous demands of various industries.